Drilling operations are planned based on seismic data and reservoir models. But even when best possible data are available, faults can remain unresolved and hazardous features like karst cavities can come as a surprise. The navigation of the drill bit with respect to the reservoir itself can sometimes remind of a walk in the fog, due to uncertainties in the velocity model.

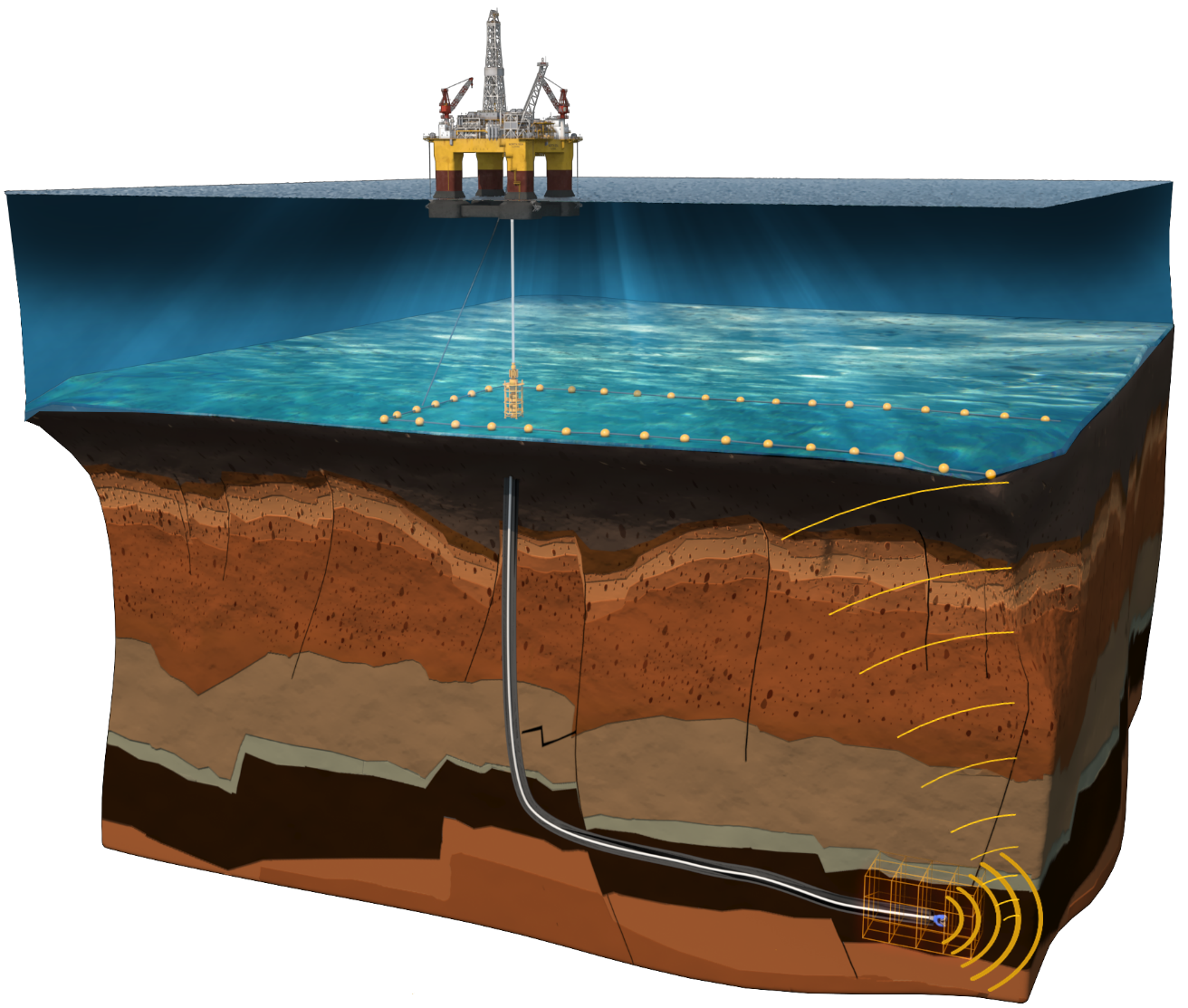

OCTIO’s DrillWatch technology is based on seismic sensors deployed on the seafloor, and uses the sounds produced by the drill bit as a seismic source. The energy emitted by the bit is used to image the surrounding geology in real time, and hazardous objects and important references ahead can be identified and located. This, together with a drill-bit positioning accuracy of two to three meters, enables the customer to make proactive drilling decisions in real time without the need to stop for logging.

While other technologies make use of resistivity contrasts, DrillWatch is based in the rock’s acoustic properties, and has therefore a wider domain of applications. The technology has been tested in several fields on the Norwegian continental shelf.

OCTIO and OGS will present results from a past pilot DrillWatch deployment in an abstract at the forthcoming SEG Annual Meeting.

A summary of all technology updates to be presented by OCTIO at SEG is provided here.